Ethylene glycol monomethyl esters (EMS, SMEPEG, MPEG) are used as a component of mixed sorbents for treating natural gas in antifreeze, hydraulic coolant liquids. Methyl cellosolve, methyl carbitol and their mixtures are used as solvents in production technology for paint materials. High-molecular weight polyethylene glycol methyl esters with an average molecular weight of over 750 – MPEG-750 and MPEG-1000 – are nonionic surfactants and are the raw material for synthesis of polycarboxylates.

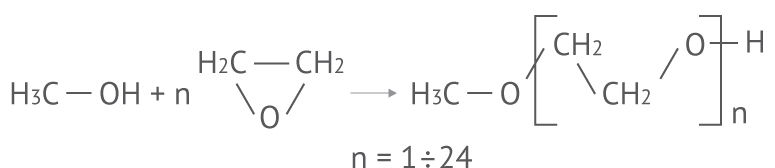

The technology for obtaining ethylene glycol methyl esters is based on the reaction of ethylene oxide with methyl alcohol in the presence of an alkili catalyst, a tertiary amine or hydroxide or alkali metal alcoholate.

By-products are polyethylene glycols due to the presence of water in the raw material. As a result of methanol oxyethylation a mixture of polyethylene glycol methyl esters is obtained. The content and distribution of methyl alcohol ester homologues depends on the initial molar ratio of ethylene oxide/methanol.

Individual methyl alcohol esters:

Separated by distillation.

The reaction mixture, consisting essentially of methyl alcohol esters with a degree of oxyethylation of over four, is not subject to separation. The product's average molecular weight is found by the hydroxyl value (mgKOH/g) or by chromotographic analysis.

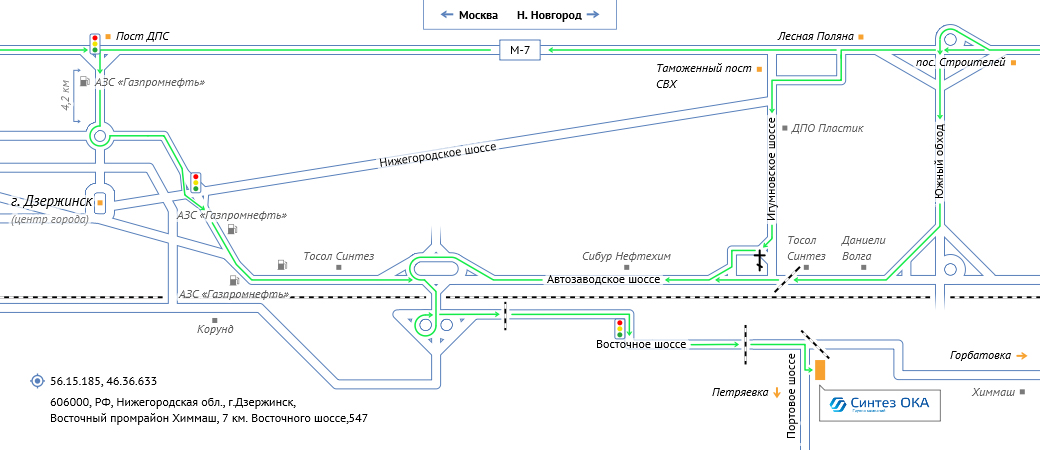

Practical implementation

The technology has been implemented at the production facilities of Sintez-OKA LLC and Caprolaktam TS LLC.