Himtek Engineering JSC is the leading Russian company in the development and organisation of ethanolamine production.

Ethanolamines are amino alcohol, organic compounds. They are obtained in industry by synthesis of ethylene oxide and ammonia. During further rectification, Monoethanolamine (MEA), Diethanolamine (DEA) and Triethanolamine (TEA) are separated out.

Ethanolamines are basic raw materials and are used in finished products in many sectors of the economy: from oil and gas processing, cement and metallurgy, to cosmetics, pharmaceuticals and agriculture.

The current global ethanolamine demand exceeds 1.5 million tonnes per year, increasing 5-7% annually.

Technology description:

Ethanolamine production consists of the following stages:

• Ethanolamine synthesis.

• Ammonia distillation.

• Rectification – separation of individual ethanolamines

Synthesis is carried out in the liquid phase from ethylene oxide and ammonia in anhydrous medium, at a temperature of 40-80 °Ñ and pressure up to 20-40 atmospheres. The reaction is autocatalytic and does not require a special catalyst. The process is characterised by high ethanolamine output and synthesis flexibility that makes it possible to adjust the selectivity for MEA, DEA and TEA formation. Efficient vacuum rectification separates high quality ethanolamines.

The technology is protected by patents of the Russian Federation 2141475, 2268255, 2141475.

Advantages of the technology:

- Safety.

- Environmentally friendly.

- High quality products.

- Energy efficient.

- Minimum consumption rates.

- High selectivity of the process for each ethanolamine.

- No waste.

- The main equipment does not require any special arrangement

Practical implementation:

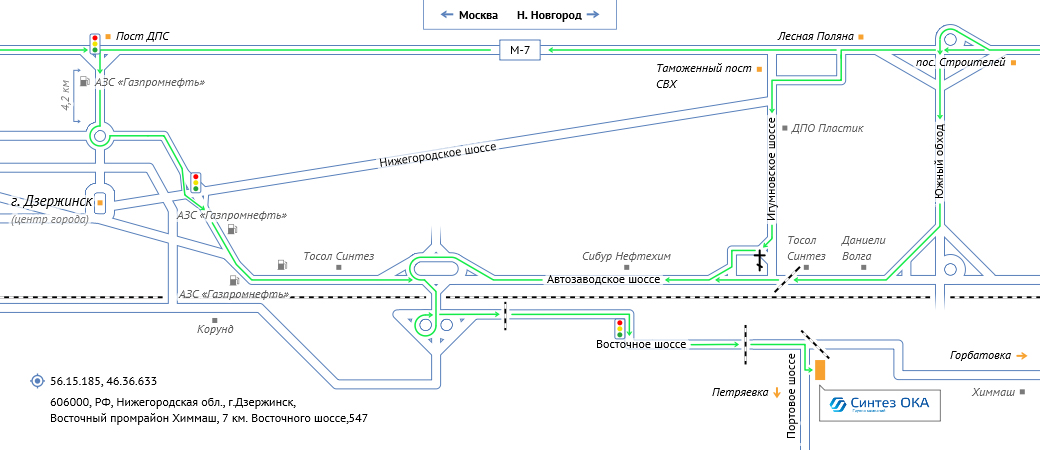

In 2001 in Dzerzhinsk (Nizhny Novgorod region), a plant was built at Sintez OKA LLC, for ethanolamine production using anhydrous synthesis, owned by Himtek Engineering JSC. In 2011, the ethanolamine separation unit was upgraded, which made it possible to begin the release of a new product, pure triethanolamine.

This is currently the largest complex in Russia for ethanolamine production, with a total capacity of 25,000 tonnes per year. The products, Monoethanolamine, Diethanolamine and Triethanolamine, meet the best international standards, which is confirmed by strong trade links with consumers from all over the world.