Himtek Engineering has universal technology for selective hydrogenation of organic compounds in the liquid phase on a fixed bed catalyst, which is particularly effective in highly exothermic reactions, such as hydrogenation of nitro-compounds, aldehydes and ketones.

Technology description

Liquid phase hydrogenation in a fixed bed reactor. Chemical reaction heat is abstracted in the heat exchanger on the reaction mixture recycling line. Hydrogenation is conducted in the target product environment without introducing solvent into the process. The product's high output is achieved by distributing the conversion of the hydrogenated compound between the main reactor and the maturing reactor. High selectivity is provided by the optimal choice of catalyst and a narrow temperature interval of the reaction mixture by reactor volume. Depending on the type of hydrogenated compound, synthesis is conducted at a pressure of 0.5-5.0 MPa and a temperature of 5°-15 °C.

The H2 drainage value is determined by the number of low-boiling impurities in the gas and liquid phases.

Advantages of the technology

- Fixed catalyst bed.

- Simple hardware and process design.

- High productivity.

- No hydrogen circulation.

- The degree of conversion is close to 100%.

- High selectivity.

- High degree of safety, no uncontrolled heating of the reaction mixture

- Low material and energy costs.

Practical implementation:

Himtek Engineering has developed the following hydrogenation technologies:

• dinitrotriethylbenzene to diaminetriethylbenzene;

• acetone to isopropyl alcohol.

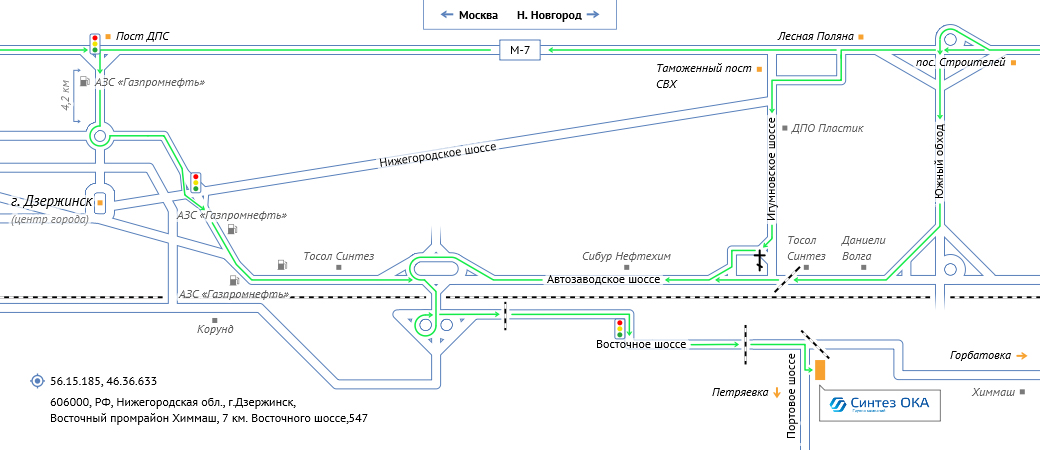

The technology for the hydrogenation of dinitrotriethylbenzene to diaminetriethylbenzene was implemented at the Spektr plant in Kemerovo.

RF patent No. 2205818 was received for the technology for the hydrogenation of acetone to isopropyl alcohol.