On February 4, 2019, Sintez OKA Group brought online a nitrogen station with a capacity of 300 m³/ h with purity of 99.95%. The station ensures all the production sites of the group with nitrogen and will also create a reserve for the company's future projects.

On the 28th of December LLC Sintez OKA-Intensive and LLC Sintez OKA-Polycarboxylates were merged in a new company Sintez OKA-Construction chemicals LLC. The purpose of the creation of the combined company is to optimize the structure and in-depth implementation of the related construction markets: cement and concrete. For the cement industry, Sintez OKA-Construction chemicals LLC manufactures additives for cement under the trademark InCem and for the concrete industry – polycarboxylate esters under the trademark Sinteflow.

Sintez OKA Group switched to its own power supply. It’s became possible thanks to the launch of a new turbine with a capacity of more than 1 MW.

Sintez OKA Group was a pioneer in the region in generating electricity using solar panels.

RUSNANO JSC, Sintez OKA LLC and Sintez Capital LLC created sector-specific fund focused on investments basically in the chemical and petrochemical industry RUSNANO-SINTEZ.

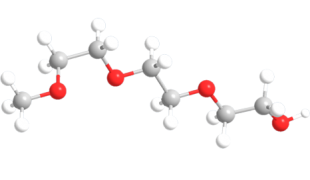

On February 1, 2018, Sintez OKA commissioned a pilot unit for the production of propylene oxide by direct epoxidation of propylene with hydrogen peroxide (HPPO). Due to close cooperation between Sintez OKA and the St. Petersburg State Technological Institute (Technical University) modern laboratories have been established to develop the process for the production of propylene oxide by the HPPO method on the Department of Oil and Coal Technology.

In 2017 Himsorbent CJSC and Prosernat (France) signed a licensing agreement that includes the use of technology, know-how and software of the process AdvAmine™ energizedMDEA, which is protected by patent of the Russian Federation No. 2201282, registered by the Federal Service for Intellectual Property: «Regenerative method for de-acidifying a gas containing CO2 and liquid hydrocarbons, using an absorbing liquid based on activated methyldiethanolamine».

Sintez OKA-Polyurethane LLC has become the sixth production unit of the chemical complex of the Sintez OKA Group. The key business of the company is the production of chemical raw materials for the polyurethane market, primarily polyethers.

On the 16th of May Himtek Engineering CJSC celebrated its 25th anniversary. Himtek Engineering CJSC was established in Saint Petersburg in 1991 by Doctor of Chemical Sciences and leading expert of the State Institute of Applied Chemistry Gennady Ryleev. The premiere of the film about the company has taken place on the anniversary celebration. Himtek Engineering today is a management, research, design, technological and engineering centre of Russia’s major amine production complex.

Construction at Sintez OKA LLC of a new plant for triethanolamine recovery with 99+ content of the main substance. The plant currently produces a high-quality product that is in demand in Russia and abroad and which complies with leading quality standards.

Years of experience of system analysis of chemical production, joint work with Russian and foreign companies in the field of chemical equipment production, design, development of new catalysts, the creation of a management and control system, allow Himtek Engineering CJSC to efficiently solve a wide range of scientific and technical challenges faced by the industrial complex in Dzerzhinsk.

Design data developed by Himtek Engineering CJSC was used to commission a distillation column for water separation from the reaction stream of synthesised ethanolamines produced by water technology at workshop No.2. This made it possible to increase the process productivity, the quality of the final products and the environmental friendliness of the technology without making significant changes in energy consumption.

Together with Himtek Engineering CJSC, an additional distillation tower was commissioned at Himsorbent CJSC for stripping intermediate distillate in MDEA production. This made it possible to improve quality and ensure the production of a product with an MDEA content of over 99%.

Himtek Engineering CJSC acquired the OKA plant from Sintez JSC (later renamed Sintez OKA LLC), which includes a complex for the production of oxyethylated products, and a share in Himsorbent CJSC. These acquisitions turned Himtek Engineering CJSC into a management company of the largest ammonia production complex in Russia, with the ability to determine the strategy for future production development and to take the position of a research, design, process and engineering centre.

Under the management of Himtek Engineering CJSC, Sintez OKA LLC and Himsorbent CJSC jointly increased production capacity by 15,000 tonnes (50%), and significantly improved the quality of produced goods while reducing consumption ratios.

New production of ethanolamine was commissioned at Sintez JSC with a capacity of ten thousand tonnes per year, using technology from Himtek Engineering CJSC, patented and based on oxyethylated anhydrous ammonia. The complex has flexibility in terms of end products (MEA, DEA and TEA), it uses energy saving and safe technology, while product quality complies with the best global standards. Production capacity has doubled thanks to the use of new patented solutions from Himtek Engineering CJSC.

Owing to RAO Gazprom's demand for diethanolamine (DEA), Himtek Engineering CJSC converted its current production of ethanolamine at Sintez JSC to new technology which is flexible in terms of the range of produced ethanolamines, MEA, DEA and TEA. As a result, the production of the demanded diethanolamine increased six fold.

Together with AOZT Astor at the Angar Electrolysis Chemical Plant for the production of uranium as part of the conversion project, the production was launched of ozone friendly R-14 refrigerants using new technologies (Himtek Engineering CJSC patent together with AOZT Astor) with fluorine and carbon. The continuing development of this project makes it possible to use surplus power for fluorine to release a wide range of organofluoric products using a chlorine-free method.

Himtech Engineering's proposal was implemented for the creation of a new product, methyl alcohol esters (physical absorbent for removing Н2S, CO2, RSH from natural and industrial gases) with a capacity of one thousand tonnes per year, using existing equipment. A new coolant was developed based on methyl alcohol esters, which surpasses DAG type coolants used at the facilities in terms of pour point, thermal oxidation stability, thermal conductivity and volatility.

he first major project was implemented in 1994 with the creation of Himsorbent CJSC in Dzerzhinsk, a manufacturing complex for ensuring import substitute products for the oil and gas sector and ammonia production plants. The company's shareholders were RAO Gazprom, Sintez JSC and Himtech Engineering CJSC. A Methyldethanolamine (MDEA) plant with a capacity of ten thousand tonnes per year (sorbent for removing acidic impurities, hydrogen sulphide, carbon dioxide, etc., from natural and industrial gases) was the first to be put into operation at Himsorbent CJSC. The process is based on state-of-the-art technology and developed and patented by Himtech Engineering CJSC. Other parts of the complex include the production of mixed special sorbents based on MDEA (capacity of three thousand tonnes per year), coolant (capacity of two thousand tonnes per year). Himsorbent CJSC is still the only Methyldethanolamine producer in Russia.

The first project was implemented in 1993. New universal technology was implemented at the Spektr plant in Kemerovo for the hydrogenation of organic compounds to replace polluting processes using iron filings. High-tech production - amine crosslinkers for polyurethane formulations - is an import substitute and is used for making parts for Russian car plants (VAZ, GAZ).

Himtek Engineering CJSC was established in Saint Petersburg in 1991 by Doctor of Chemical Sciences and leading expert of the State Institute of Applied Chemistry Gennady Ryleev.

The main reason to set up the company was the opportunity to implement knowledge in the field of innovative technologies for the production of different chemical products.

Despite the fact that the specifics of Himtek Engineering's business at the time of its foundation were new and unfamiliar for the domestic market, it immediately became clear from the number of requests and orders that such services were in great demand. The technology used by many Russian chemical plants was outdated, energy consuming, unsafe and product quality lagged behind that of similar foreign plants.

For the contribution to the victory the plant employees were awarded the Order of the Red Star, the Order of Red Labour Banner, order of Badge of Honor, Medal of Honour for Labour Valour and For Distinguished Labour.