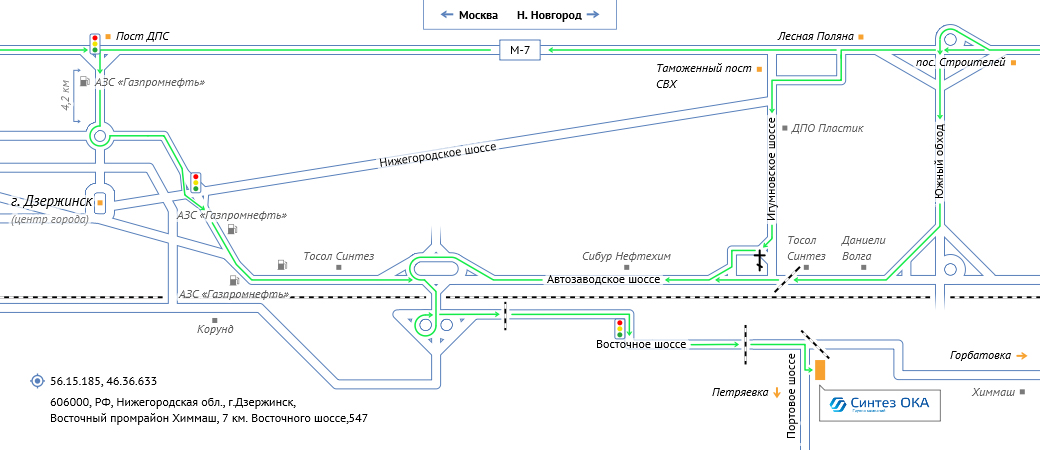

The world's practice analysis accumulated in purification of natural and process gases treatment from acidic impurities, including H2S, CO2, COS, CS2, mercaptans, indicates that the main process for treating large gas flows is the use of a chemical and physical absorbents and combinations thereof. Monoethanolamine, diethanolamine, triethanolamine, methyldiethanolamine are commonly used as chemical absorbents in production process. As physical absorbents ethylene glycol methyl ethers are most commonly used. Sintez OKA Group of Companies is a manufacturer of all products listed above, and that allows it to dominate among supplies of absorbents to conditioning (purification) natural and process gas from acidic impurities and to prepare for natural gas liquefaction.

When developing new solutions for natural and process gases treatment Sintez OKA Group of Companies takes into consideration the latest technologies and the experience of Russian and foreign specialists. Long-term cooperation with leading Russian and foreign companies in the field of gas treatment has allowed developing balanced technologies for customer-specific applications. In 2013 Himtek Engineering JSC has been granted the right by BASF to sub-license BASF's OASE yellow and OASE purple technology. This includes new solutions for selective treatment of natural gas amongst others.

The production of the Sintez OKA Group of Companies has been used successfully for gas treatment processing in CIS and Russian gas processing plants such as Gazprom, Lukoil, Rosneft, Tatneft.

Absorbents manufactured by the Group are also widely represented at ammonia producing factories.

Sintez OKA products have a successful record of application for gas treatment at oil refineries and gas processing plants of such major companies in Russia and CIS countries as Gazprom, Lukoil, Rosneft and Tatneft. Our absorbents are also high in demand among ammonia manufacturers.

Sintez OKA focuses its gas treatment activities in the following areas:

- development of new amine treaters;

- switch to new absorbents, and

- continuous cooperation with current absorbent consumers.

Our customers enjoy an integrated approach: technologies, absorbent solution and service:

Our work starts with the diagnostics of a gas treatment unit. Equipment that has been used for a while usually accumulates a number of problems related to its unsatisfactory operation, poor cost effectiveness, etc. We send a questionnaire to the relevant enterprise, requesting it to specify the unit configuration and specifications and express performance improvement expectations. As a next step, we analyze the feedback, visit our customer, if necessary, and make preliminary calculations. Based on our findings, we offer provisional recommendations on an action plan to improve the gas treatment unit performance.

Service

Operation guidelines

We always keep in touch with our clients and customers. Having designed a gas treatment unit or supplied an absorbent, we never leave our partners alone to solve their problems, if any. We consult our customers at each product introduction phase, from initial calculations to commissioning. Where necessary, we perform a field analysis of amine solution composition and develop recommendations on the optimum process involving our absorbent. Moreover, our customers may always rely on our advice when it comes to analytical support of production process using our absorbents.

Consultation

on treatment unit start-up with new sorbent and on replacement of spent one

We provide our customers with detailed consultations when an absorbent needs to be replaced. Usually, the properties of new and old absorbents differ. In addition, charging and discharging operations feature a variety of details. Neglecting such details may even provoke a shutdown and long outage due to repairs. We do our best to help avoid these troubles.

I. A. Lavrentyev, Gas Treatment Director

Verification

analysis, choice of technology, absorbent selection

As soon as the primary analysis of the customer's unit is complete and the performance improvement opportunity is identified, we proceed with detailed calculations and identification of main operating parameters and gas treatment process conditions. We select the best absorbent in every respect. Verification analysis of the customer’s equipment is an essential part of our activities. In certain cases, when an absorbent is replaced with a new one, some equipment (e.g. pumps) may require upgrading.

With HYSYS 8.4, a software suite featuring the special amine treatment process modeling package, and solid experience in switching refinery amine treaters from MEA to MDEA, we always cope with our tasks successfully.

Basic

engineering for new treatment units

Enjoying great expertise in chemical plant design and professional competence in amine treatment technology, the research team of our company, including a Doctor of Chemistry and a few Ph.D. in Engineering, is able to perform basic engineering tasks to make gas treatment units of various profiles. We are committed to the idea that right unit configuration is a key to high availability and cost-efficient operation. The better process parameters are coordinated and the better configuration is adapted to the previous unit in the process flow, the less troubles occur in the course of production which often involves amine treaters.

Feasibility study

Project feasibility study

Improved cost-effectiveness is the principal objective of any unit development or upgrading project. We always conduct a feasibility study within the project. It is an integral part of upgrading operations and may have a decisive influence on the engineering aspects of the project.

Documentation

Product specifications, analytical procedure, physical properties of products

Either developing a new unit or upgrading an existing one, we provide all relevant regulatory documentation for products and substances used in design. Therefore, specifications, safety data sheets, certificates and permits for our absorbents are always available to our customers. Moreover, we furnish them with analytical procedures crucial for normal process flow. Design and process documentation also include the physical properties of substances to ensure safe and efficient manufacturing.

Solution

Optimum solution for each unit

Sintez OKA Group manufactures a variety of absorbents for amine treatment, in particular individual amines, composite absorbents and physical absorbents. The fields of their application are numerous and include gas processing, oil refining, chemical industry, etc. We customize the best absorbent composition for each particular unit.